How to calculate inch diameter of pipe?

time2021/01/08

- How do we calculate inch diameter of pipe? There are so many expressions of pipe size, how can we find suitable tools for our own working conditions, such as threading machine, grooving machine and so on? The key bit of information is that pipe sizes are inside dimensions.

How to calculate inch diameter of pipe?

As others have said, the nominal dimension of pipe is the area inside the pipe walls. You can use a rule for crude measurement or a caliper for more precise measurement. But in some pipe related field, there are some statements of OD, DN and SCH. As different cognition results from different standards, we are always confused.

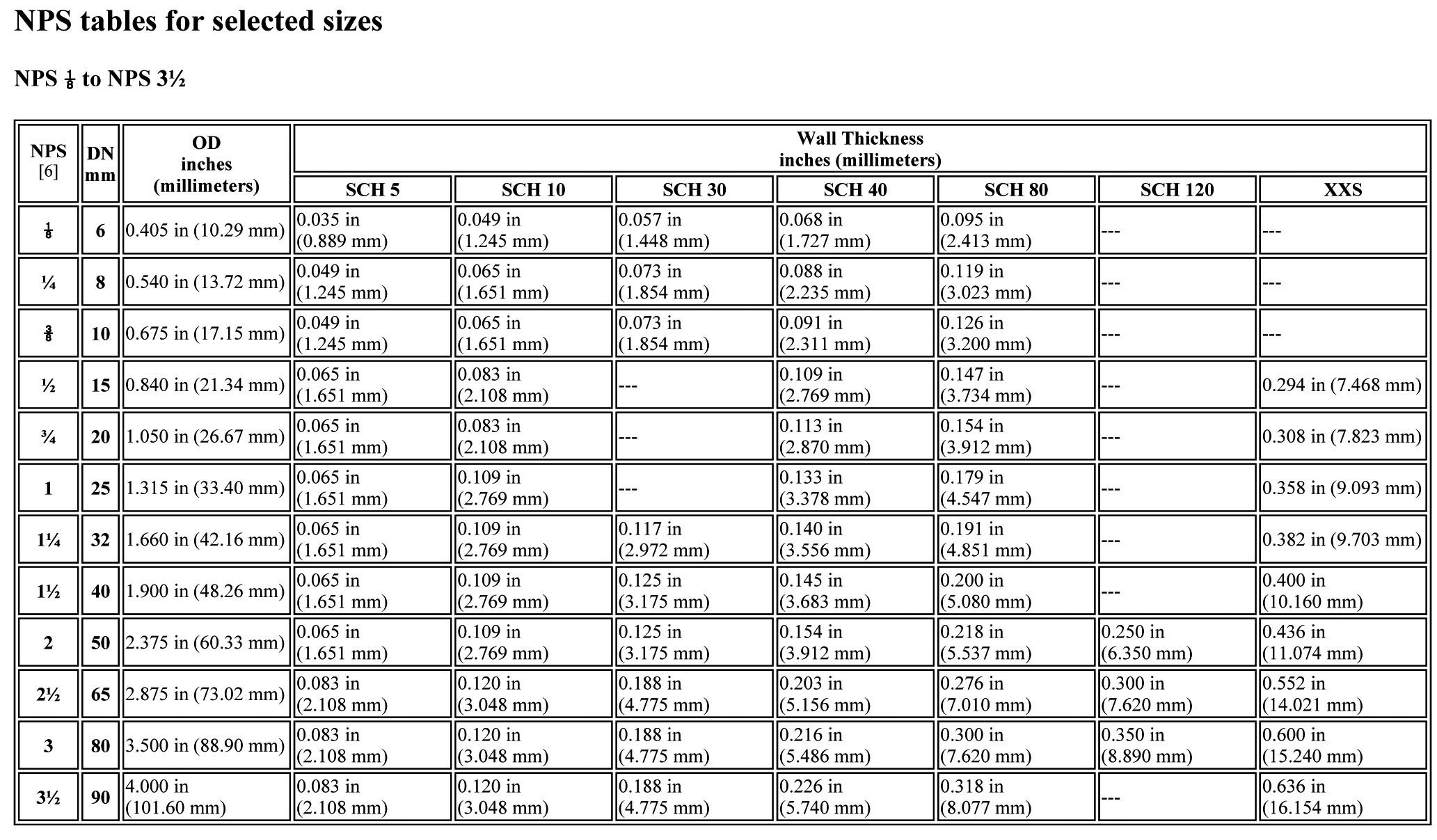

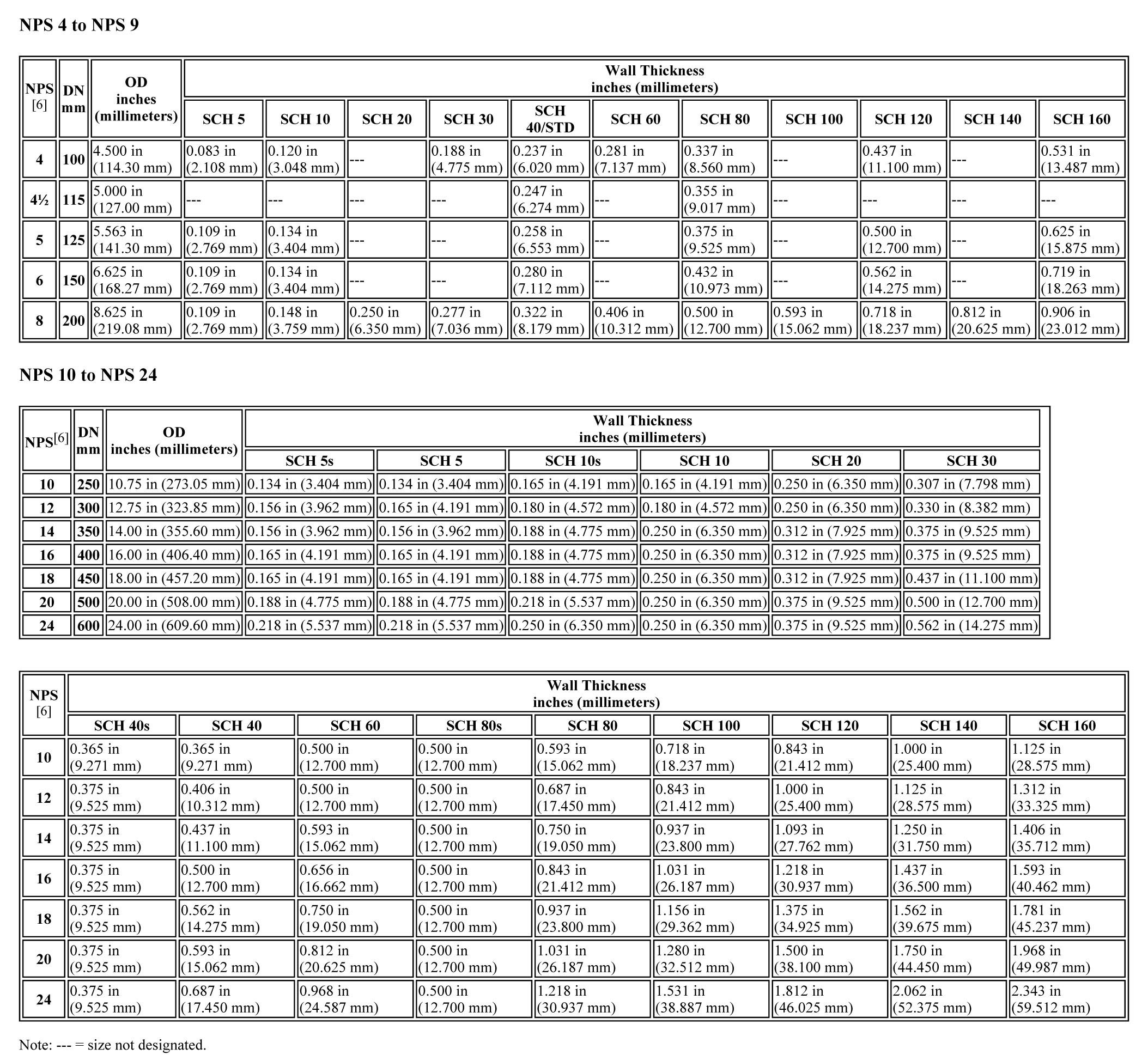

Conversion tables are available below to help you convert metric dimensions to inches.

In the calculation of pipe diameter, the key bit of information is that pipe sizes are inside dimensions.

For example, various “schedules” (SCH is wall thicknesses) of 1/2″ pipe will all be 1/2″ inch inside diameter, but their varying wall thicknesses will cause the pipe to be varying outside diameters.

1/2″ schedule 40 steel pipe, for example, will be somewhat larger than 1″ in outside diameter, while thinner wall pipes of the same 1/2″ capacity will have a thinner outside diameter.

In most conventional household pipes, 1/2″ pipe thread will be standardized to the dimensions of conventional steel 1/2″ galvanized or black steel pipe. Fittings used on other types of pipe, for example 1/2″ sweat copper, will be sized to fit that “galvanized pipe” standard, even though the wall thickness of the copper may create a fitting that is slightly larger than 1/2″ inside diameter.

That’s where the term “nominal” dimension comes from. While the inside diameter of 1/2″ copper pipe and 1/2″ galvanized pipe is precisely 1/2″ inside diameter, the standard for the outside threaded section of adapters and fittings is all based on the galvanized pipe convention. The same would be true as you upsize the pipe to even much larger dimensions. Why? Because pipe thread must be a universal size for the “female” (inside) thread and the “male” (outside) thread so that all types of pipes can be joined together with threaded joints.

This convention creates a lot of confusion, that pipe thread is tapered slightly so that as you tighten the joint, the joint gets tighter. If you measure male 1/2″ pipe thread at the very end of the pipe, you’ll notice that it’s both slightly smaller and the threads are deeper. As you move back from the tip of the pipe about 1/2″, you’ll notice that the diameter increases to the full outside diameter of the pipe and the threads get increasingly shallow.

Hongli pipe machinery, a manufacturer of pipe machines and tools, is specialized in pipeline connection started from 1986. Pipe threading machines, pipe grooving machines, pipe hole cutter and drain cleaning machines etc. are our main categories.

Hongli Pipe Machinery is intended to provide customers with pipeline construction, installation, testing and maintenance solutions.